Perhaps it’s their versatility, or perhaps it’s the wide range of surfaces they can cover, but few things benefit a good surface prep job like a quality scarifier. That’s because, between their attachments and the various models available, scarifiers present a dynamic opportunity for workers approaching projects with complex needs. Whether you’re stripping paint or roughening a concrete surface, the scarifier—and its many makes and models—is ready to take on the job.

At Runyon Surface Prep, we offer Von Arx scarifiers with an array of capabilities. This post will explore the possible applications for these scarifiers, as well as their necessary attachments and potential coverage per unit. Stick around to learn more!

Get to Know Your Scarifier’s Various Uses

Scarifiers are usually one of the first tools you use in preparing your surface for coating or installation. While some surface prep equipment and machinery have a single purpose, scarifiers stand out in that their applications will vary depending on your needs. Typical applications for scarifiers include:

- Removing coating, epoxy, and glue

- Concrete grooving for anti-slip on-ramps and sidewalks

- Correcting concrete joints

- Lippage removal

- Eliminating trip hazards

- Concrete stock removal for fast aggregate exposure

- Removing traffic lines, rubber deposits, dirt crusts, and plastic coatings

Of course, adjustments should be made if you’re hoping to take advantage of the scarifier’s multi-purpose nature. While not every scarifier is capable of all the above uses, many are able to adapt for a variety of demands – you simply need the right cutters.

Know What Cutter to Use and When to Use It

You’ll need to change attachments from application to application before you move on to a different use for your scarifier. Cutters are manufactured to have different impacts on the surface in question. Your set for paint removal, for example, would likely be different than the set you use to remove plastic markings.

The range of Von Arx cutters include:

- Pentagonal, Octagonal, Hexagonal, Bihexagonal carbide cutters with tungsten tips: roughens concrete and asphalt and removes old coatings

- Beam: removes road markings and paint from asphalt and concrete and intended for work with large steel structures or material with only a light expected change of surface structure

- Milling: removes and strips thermoplastic and cold plastic coatings and markings

Your attachments play an integral part in prepping your surface for an installation and many scarifier drums allow for an easy switch from cutter to cutter, adding versatility to your work. That said, you can only get so far in your investment without the right scarifier model.

So, What Model Is Best for Your Project?

When it comes to Von Arx scarifiers, Runyon carries push and self-propelled models powered by gas or electricity. From power output to width of surface coverage, the capabilities of these unique models vary quite significantly. Typical models are:

VA10

With a 4” surface cutting width, the lightweight VA10 electric scarifier is great for less demanding projects like one-off garage installations or a few small rooms. This is the perfect machine for hard to reach areas and edge work. It weighs around 50 lbs and runs at about 1.5 HP.

FR200

Available in gas- or electric-powered options, the FR200 covers a cutting width of 8” and surface depth of 1/10” – making it ideal for small and medium sized surfaces. Electric options come in either 110V or 230V with 2 HP or 3HP motors and making the switch between cutters on the FR200 takes just a few minutes.

VA25 S

The VA 25 is the machine of choice for medium and up to large surfaces. It has a working width of 10” and is available in gas or electric. It is equipped with a vibration absorber and an infinite variable depth adjuster, the flexible VA 25 offers the highest level of user comfort and efficiency.

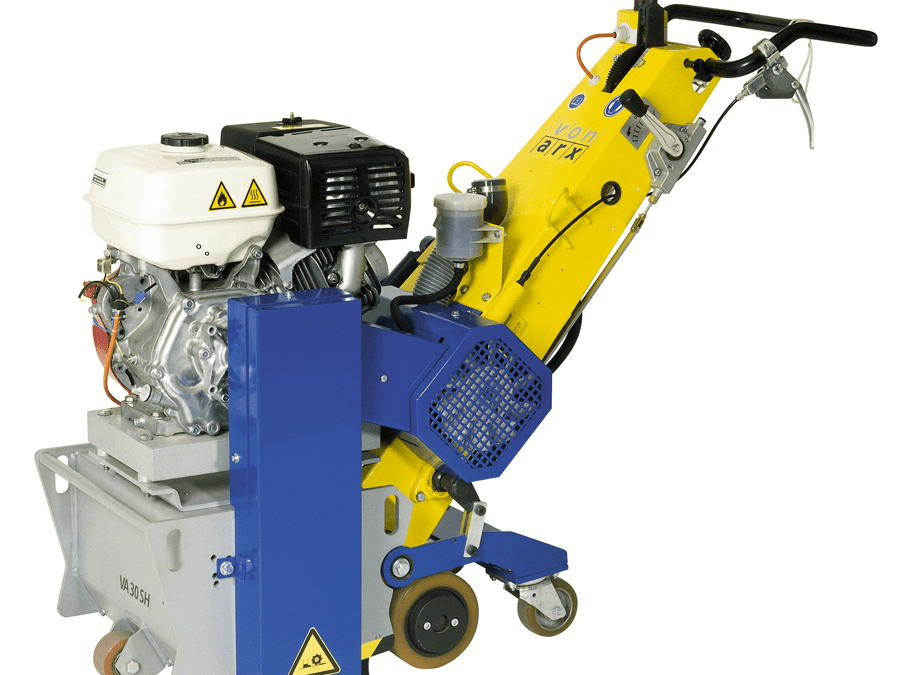

VA30S & VA30SH

Both the VA30S and the VA30SH are built for heavy-duty challenges—covering 12” width and up to 1/3” of hard surface depth—and come equipped with variable depth adjusters and vibration absorption systems. The VA30S and the VA30 SH may both be found in gas or electric options. The VA30 S is a “push unit” and the VA30 SH is self-propelled. What separates the VA30SH from the VA30 S models, is the hydraulic traction that boosts the machine’s agility and makes for a much easier use.

Scarifiers, Grinders, Coatings – Whatever You Need for a Job Done Right

Before you get started with your surface work, be sure you have everything you’ll need to do the job efficiently. Runyon Surface Prep is a full-service sales and rental facility with a wide range of tools and equipment necessary for a thorough surface installation.

In addition to Von Arx scarifiers, we carry floor grinders, power trowels, scrapers, epoxy resin and polyaspartic coatings, and much more. We also offer training services for power-trowel systems. Runyon has offices in Carmel, Indiana and the Sacramento area and offers same-day shipping! Reach out today to learn more.